Production capacity: up to 140 t / h, allowing the use of up to 30% recycled material

Counterflow Dryer: increased drying efficiency with Multi Fuel Burner (light oils, heavy oils, GLP / GN)

New mixer: Multi Paddle Pugmill®

New Infinity Control® Control System: with remote access for maintenance and monitoring / telemetry

Higher capacity in 4 silos aggregates: capacity of 10 m³ each / 40 m³ total

New dispensing silos: 30% more capacity

• 4 silos with individual capacity of 10 m³, totaling 40 m³ of

capacity – integrated into the chassis;

• Greater autonomy during the process;

• It allows the use of large loaders (internal width

two 3,700 mm silos);

• Saving time and fuel with the charging process.

Dryer with Higher Drying Efficiency / Multi Fuel Burner

• Largest drying area of the category (2,200 / 1,800 x 6,600 mm):

– Perfect distribution of fins;

– Thermal insulation;

– Better thermal efficiency and better fuel economy;

• Burner CF-04 Marini Multi Fuel (heavy and light oils, glp, gn);

– Low fuel consumption;

– Safety system: flame sensor and fuel shut-off valve.

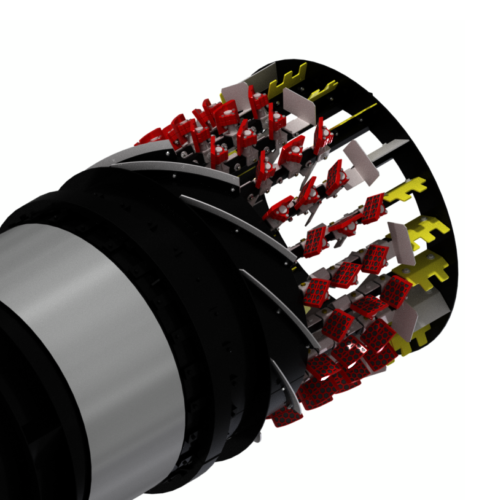

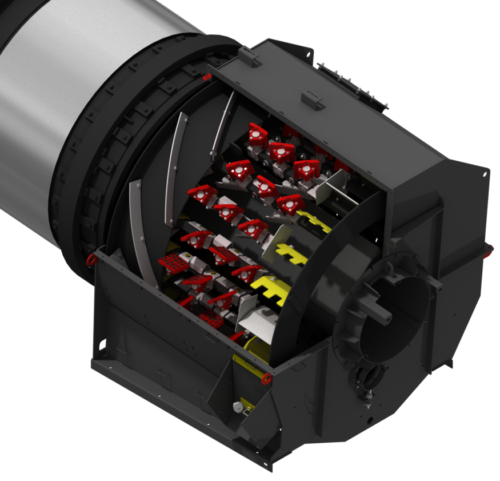

New mixer with Pugmil® Multi Paddle technology

New mixer with Pugmil® Multi Paddle technology

• New format with multi blades: more blows per particle during the process;

• Longest mixing time processing in the category: vanes with position adjustments for different service conditions

and reposition after wear, providing an increase in the useful life;

• Self-cleaning vane;

• Wide ease of maintenance: allows the change and adjustment of the vanes in an ergonomic position through the upper cover of the

mixer – mixer body built in five parts;

• Drag Mixer® fins at the mixer outlet: they provide even longer residence time and homogenization of the mix.

New Infinity Control® booth and control system

• Ergonomics combined with excellent positioning:

– Far from loading silos;

– Wide visibility of the entire work area;

• Infinity Control®: total control of the entire process;

• High-definition touch screen. Also has access by mouse and keyboard;

• Remote remote access;

• Telemetry: Have the plant in the palm of your hand, with specific managerial reports;

• Allows indication of maintenance time and record of maintenance performed;

• Video camera to view the burner flame.

Drag lift with anti-segregation and silo 1m³

• Drag Mixer® anti-segregation system and better

homogenization in the transportation of the asphalt mass;

• Silo with large width bi-start

discharge and quick opening and closing system:

avoid segregation of the asphalt mass.

Prepared for standard nr-12

• Protection of conveyor belts, rollers and dryer rings;

• Emergency touch cord on the straps;

• Emergency switches located at strategic points of the plant;

• Power panel separate from cab;

• 24 Vdc control voltage;

• Life line.

Double filter option filter material filter

• Excellent filtration area with 400 conventional polyester or Nomex smooth sleeves;

• Emissions of particulate matter less than 50 mg / Nm³;

• Low maintenance cost due to smooth sleeves.

After-sales support

After-sales support